Vacuformer – endless pressing applications!

The Vacuum press für Furniere, Holz und Stoffe.

Die vielseitigen, funktionalen und wirtschaftlichen Vakuumpressen für alle Pressprozesse im Holz- und Kunststoffbereich. Maßgeschneiderte Modelle für Ihre spezielle Aufgaben in unterschiedlichen Tischgrößen mit der bewährten Klappenöffnung oder der leistungsstarken Vertikalbewegung.

Alle Holzwerkstoffe und Plattenmaterialien, Furniere, Kunstleder, Filz und Stoffe, Kunststoffe, Metall- und Kunststofffolien, HPL, CPL

VACUFORMER VORTEILE

bonding – coating - edge banding - flat pressing – forming – gluing - laminated bending – pressing - spot on profile fitting - veneering

Exakte Verpressung jeder Form und Kontur – Perfekte Furnierung

flach oder gebogen – Fehlerfreie Beschichtung und Verklebung

Passgenaue Anbringung von Kanten und Profilen – Präzise Umformung heißer Werkstoffe

reinforced trussed pressing frame

sturdy industrial range

easy and fast changing of various membranes

with air evacuation channels for fast vacuum build up

integrated in the machine, on the side, or separate control cabinet

200l - 500l for a speedy air evacuation

Mehr Informationen finden sie in den Datenblättern

Hier gehts zu den Downloads

VACUFORMER MODELLE

VACUFORMER STANDARD

VACUFORMER S VERTICAL

VACUFORMER L

VACUFORMER XL

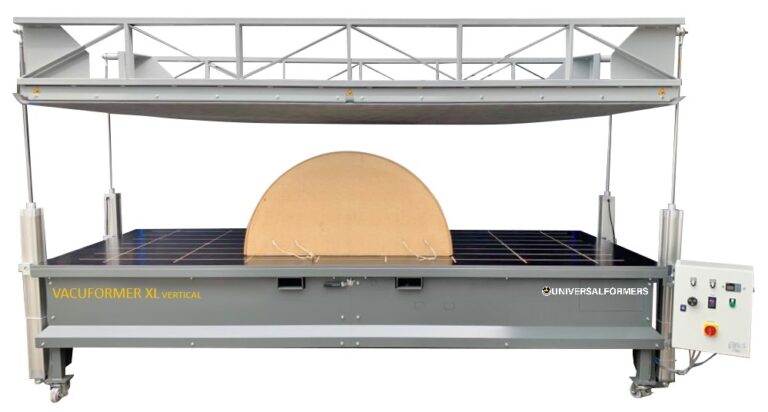

VACUFORMER XL VERTICAL

VACUFORMER XL HEATING

High-end technology

- Manually or automatic pressing

- Fast pressure build up with combination of tank/vacuum pump

- Pressure of 8.5 to/m² up to 10,0 to/m² on all sides

- Membrane fast-change system for all membranes (natural rubber, silicone, polyolefin films, high temperature films) in any thickness

- Tough, maintenance free industrial vacuum pumps (Becker, Busch)

- Standard vacuum pumps oil free (Rotary vane and dry claw pumps)

- For special customised models, oil lubricated rotary vane pumps (Busch)

- Simple and easy to understand machine operation

Solid machine building

- Sturdy and robust steel construction

- Fully welded industrial design, for daily hard working conditions

- Quality components

- Long service life guarantees amortisation of the machine

Advantages of the Vertical Movement

Limitless pressing possibilities through advanced machine design!

Outstanding pressing results

Vacuformer – versatile, functional and economical!

VACUFORMER STANDARD

The inexpensive, robust and versatile vacuumpress!

VACUFORMER S – vertical opening

The big, robust and versatile vacuumpress!

Dimensions

Compact Models

Standard vacuum pump 40m³/h

Vacuformer Education

clamshell opening, work piece height approx. 500 mm

pressing surface L x B: 2000 × 1280 mm

overall dimensions L x B x H: 2120 x 1400 x 1000 mm

vertical opening 650 mm

pressing surface L x B: 2000 × 1280 mm

overall dimensions L x B x H: 2400 x 1560 x 1400 mm

Vacuformer Standard

clamshell opening approx. 500 mm

pressing surface L x B: 2930 × 1320 mm

overall dimensions L x B x H: 3100 x 1400 x 1000 mm

vertical opening 850 mm

pressing surface L x B: 2880 × 1280 mm

overall dimensions L x B x H: 3400 x 1560 x 1400 mm

VACUFORMER L– clamshell opening

The big, robust and economical vacuumpress!

VACUFORMER L with spring support – the mechanical solution

without disturbing side struts!

VACUFORMER XL with pneumatic support

The comfortable pneumatic opening - protecting the operators back!

VACUFORMER L and XL with heating hood

For shorter pressing times!

VACUFORMER L und XL VERTICAL

The big, professional and extrem loadable vacuumpress!

For tailored pressing results!

Dimensions

Large Models

vacuum pumps 40m³/h, 80m³/h, 100m³/h, 140m³/h

clamshell opening approx. 650 mm

pressing surface L x B: 3880 x 1540 mm

overall dimensions L x B x H: 3900 x 1760 x 1000 mm

vertical opening 1000 mm

pressing surface L x B: 3880 x 1540 mm

overall dimensions L x B x H: 3950 x 1760 x 1400 mm

clamshell opening approx. 650 mm

pressing surface L x B: 3880 x 1780 mm

overall dimensions L x B x H: 4100 x 2000 x 1000 mm

vertical opening 1000 mm

pressing surface L x B: 3880 × 1780 mm

overall dimensions L x B x H: 4100 x 2000 x 1400 mm

clamshell opening approx. 650 mm

pressing surface L x B: 3880 x 2250 mm

overall dimensions L x B x H: 4100 x 2400 x 1000 mm

vertical opening 1000 mm

pressing surface L x B: 3880 x 2250 mm

overall dimensions L x B x H: 4100 x 2400 x 1400 mm

Dimensions

Foldable Model

Standard vacuum pump 40m³/h

clamshell opening approx. 500 mm

pressing surface L x B: 2930 × 1320 mm

working table unfolded:

overall dimensions L x B x H: 3200 x 1550 x 980 mm

working table folded:

overall dimensions L x B x H: 3200 x 850 x 1420 mm

VACUFORMER XL- HEATING

The big, professional and extrem loadable vacuumpress!

Even more versatile with a mobile heating station!

Dimensions

Vacuum press with a compact, movable heating station

Vacuformer XL HEATING

vertical opening 1000 mm

pressing surface L x B: 3880 × 1780 mm

overall dimensions L x B x H: 5000 x 2200 x 1500 mm

mobile heating station, free standing

heating surface L x B: 2680 × 1250 mm

overall dimensions L x B x H: 3600 x 1760 x 650 mm

Other dimensions for all Vacuformer models are possible on request!

Vacuformer – More Vacuumpower! Future proof your business today!

Vacuformer with added benefits for your production

- High productivity

- Operational without setup time

- Oil free vacuum pumps and drives

- One pressing cycle for several working steps

- One machine for pressing of all materials

- Efficient use of the working surface

- Shortening of production steps

Vacuformer with added benefits for your company

- Expansion of your production range

- Customer acquisition with more potential for innovative ideas

- Performance gain of inspired staff through easy operation, leading to perfect pressing results!

- Cost cutting and time saving

- Long lasting and robust vacuum press for veneer, wood and plastics - Made in Austria for life! made in Austria for life!

.

Universalformers Eine Marke der Lechenauer GmbH www.lechenauer.at