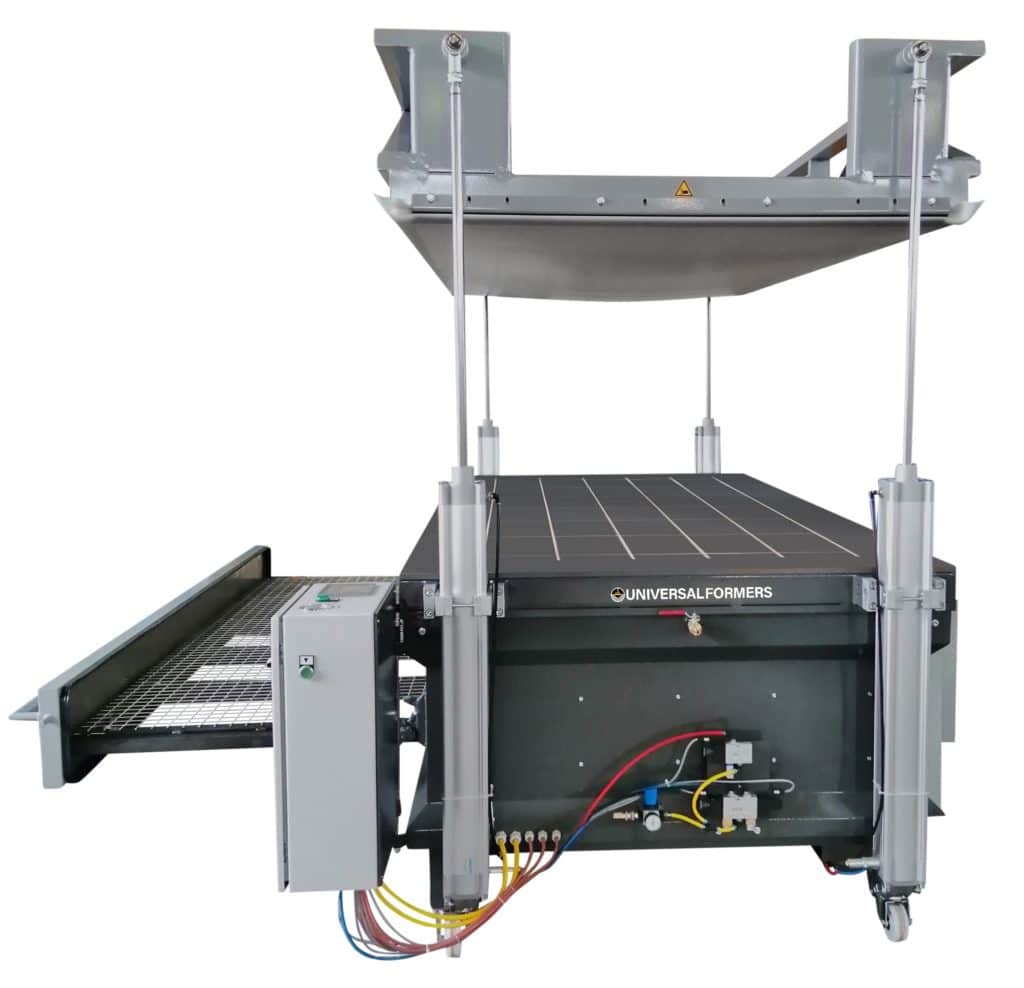

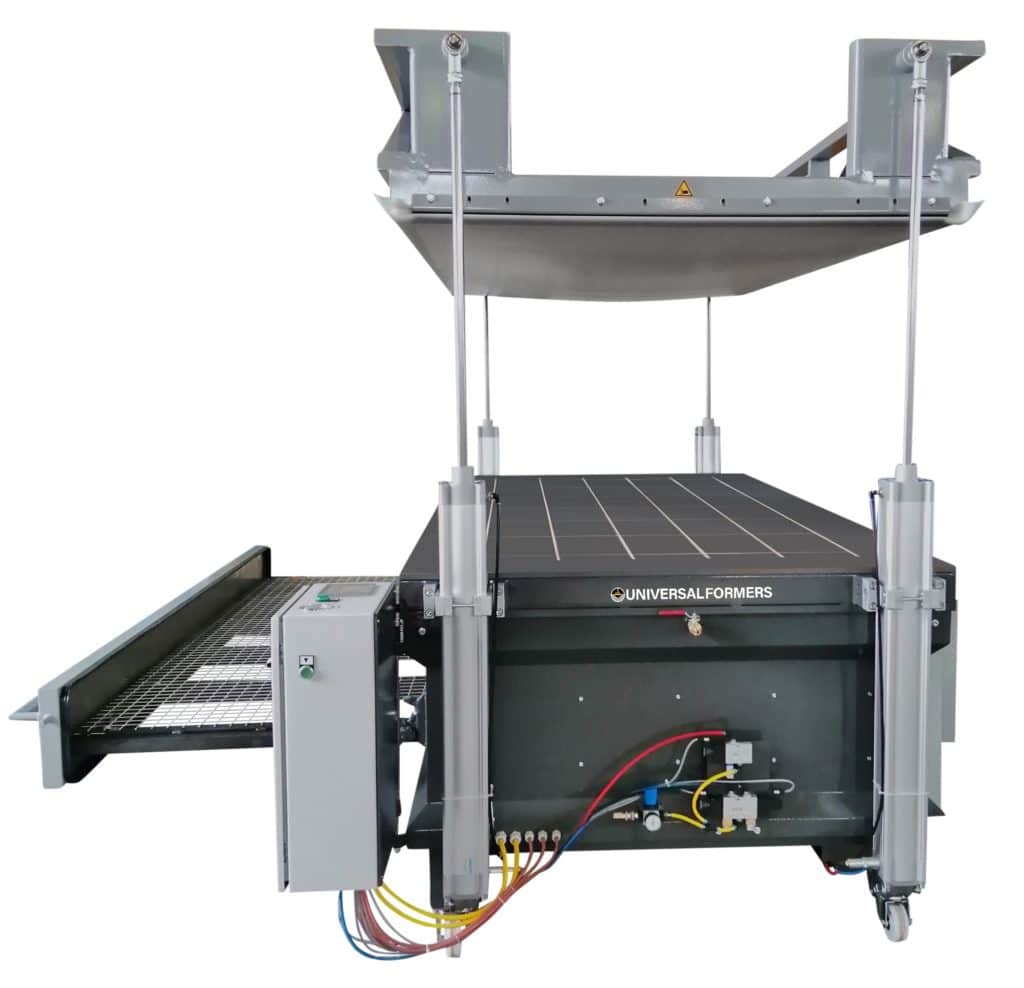

DUOFORMER - Die Vakuumpresse mit Heizung

DUOFORMER FOR SOLID SURFACE MATERIALS

Die kombinierte Vacuum press mit Heizung ist sehr kompakt und platzsparend. Diese Zwei-in-Eins-Verbindung ermöglicht es, thermoformbare Werkstoffe in unterschiedlichen Stärken und Qualitäten mit der ausgeklügelten *CAS-Umluftheizung rasch und absolut gleichmäßig aufzuheizen. Anschließend wird der erwärmte Werkstoff mit Vakuumdruck über eine Form in das gewünschte Werkstück umgeformt.

*CAS=Controlled Air Stream

DUOFORMER VORTEILE

Forming and pressing either with the well-established clamshell opening or the high performing vertical movement.

Pre-heating and forming of solid surface materials such as:

CORIAN, HIMACS, KERROCK, HANEX, STARON, MISTRAL, AVONITE, TRISTONE, VELSTONE, WILSONART, GETACORE, RAUVISIO, VARICOR, PLEXICOR, MEGANITE, KRION, LIVINGSTONE, MARLAN, EOS, FORMICA, MYSTERA, etc.

Pre-heating and forming of all other thermoformable materials such as:

ABS, PMMA (Plexiglas, Perspex, Lucite), PET-G (Vivak), PE, PS, PP, PVC-U, PC (Makrolon), UPM-GRADA, RESYSTA, NFPP, etc.

Vacuum press

for bonding, coating, edge banding, flat pressing, forming, gluing, laminated bending, pressing, spot on profile fitting, veneering

Fully welded steel construction in a double chamber system. The thick-walled steel profiles take the tensions when the machine is heated.

Weitere Vorteile:

Thermische Trennung mit zusätzlicher Isolierung zwischen Heizstation und Vakuumtisch, die Heizenergie bleibt in der Heizkammer.

Leistungsstarkes und effizientes CAS-Heizsystem (Controlled Air Stream) für die gleichmäßige Aufheizung aller Materialien!

Vacuum press mit Heizung in Temperaturbereichen bis +230 °C!

An additional feature is the easy removable heating drawer for annealing of plastics and pre-heating of voluminous work pieces.

Hitzegeschützte Bedienungselemente in einem separat schwenkbaren Schaltschrank.

Innovative und solide Vacuum press, siehe Vacuformer

Membran-Schnellwechselsystem für alle Membranen (Naturkautschuk, Silikon, Polyolefinfolien, Hochtemperaturfolien) in jeder Stärke

Einfacher Arbeitsablauf – schnell vom Werkstoff zum Werkstück!

energy saving und sehr wirtschaftlich.

Mobile Arbeitsstation – kann überall in der Werkstatt eingesetzt werden.

Wertbeständige und robuste Maschine – Made in Austria for life!

Duoformer features

fully welded, sturdy and robust steel construction

easy opening and closing

easy and fast changing of various membranes

with air evacuation channels for fast vacuum build up

temperature +230°C, pull out function and easy removable

hinged on the right side

heat resistant, very stretchy, transparent silicone membrane

Mehr Informationen finden sie in den Datenblättern

Hier gehts zu den Downloads

Extra, precise pressing power with bulky and complicated parts!

Duoformer - Clamshell Opening

Heating and pressing machine adding value to your products!

DUOFORMER

Future proof your business today!

Universalformers Eine Marke der Lechenauer GmbH www.lechenauer.at