ULTRAFORMER - bringt sie vorwärts!

Innovation durch Vakuum- und Thermopressen

This versatile vacuum press and thermoformer easily covers your existing manufacturing tasks and enables you to open new business opportunities in new markets.

The Ultraformer gives you an innovative push forward – you can make the impossible – possible; with the combination of vacuum pressing and thermoforming!

The industrial heating hood with a flexible deep drawing system plus a high performing heating drawer in combination with a vertical pressing movement will conquer any heating or pressing process!

ULTRAFORMER VORTEILE

Deep drawing - heating and forming of thermal materials – foil laminating – vacuum pressing – composites – sublimation

The multifunctional thermopress unit!

- A truly universal machine with endless production opportunities..

- Realisation of challenging and demanding projects with the adaptable Thermoforming Press

- Infinite possibilities in wood, plastics and special components manufacturing.

Ultraformer features

bis +210°C, mit CAS Umluftheizung

with 3 subframes

easy and fast changing of various membranes

sturdy industrial range

machine grade aluminium, fine grinded

temperature +230°C, pull out function and easy removable

mobile on the side

Mehr Informationen finden sie in den Datenblättern

Hier gehts zu den Downloads

The 6 in one production capabilities

Prototypes and big, complicated single parts can be produced fast and cost effectively with the Thermoforming Press.

Utilisation of all plastics and formable materials. Utilisation of all plastics and formable materials. The permanent hot air stream allows you to thermoform difficult plastics on a case-by-case base without pre-drying. All thermoformable plastics such as:

such as ABS, PMMA extruded and cast PVC, PC, PET-G, PE, PS, PVC-U, EPVC, PC, PPE, TPO, etc.

Applications:Werbeobjekte, Kunststoffschalen, ganze Thekenabdeckungen, Duschabdeckungen, Maschinenverkleidungen, Küchendisplays, Werbeschilder mit Buchstaben.

The Thermoforming Press can use all PVC 3D-furniture foils, Kydex, Boltaron and special foils/films made from any plastic.

Laminating of flat and voluminous, tall parts.

Anwendungen: Folieren von großflächigen Möbelfronten, Badezimmerkorpusse, Küchenteile, Ladenzeilen, Werbematerialie

Kompositwerkstoffe mit unterschiedlichen Materialien für Leichtbau und höchste Belastungen herstellen. Prepreg-Matten aus Phenolharz und Epoxidharz zu Fertigteilen umformen. Futuristische, endlose Gestaltungsmöglichkeiten in einem aufkommenden Markt.

Applications: Fahrwerkskomponenten, Verkleidungen, Leichtbauteile, Carbonfaserteile für Objekteinrichtung, hochmoderner Laden- und Objektbau.

Unbegrenztes Biegen und Formen von Mineralwerkstoffen, Kunststoffen und Kompaktschichtstoffplatten mit der Aufheizstation, Heizhaube und Vakuumpresse.

Mineralwerkstoffe wie: CORIAN; HIMACS; KERROCK; STARON; AVONITE; HANEX; GETACORE; RAUVISIO; etc.

Neue Thermoformwerkstoffe: UPM-GRADA, RESYSTA, CROWN LAMINATES, NFPP

Anwendungen: Bäder, Waschbecken, Theken, Verkleidungen, Küchen, Arbeitsflächen, gehobener Innenausbau, individuelle Formgebung für Möbel und Gegenstände

Sublimating and forming of whole solid surface boards (Corian, Hi-Macs, Kerrock) sublimieren und umformen. MDF-Platten und HPL-Tafeln mit Motiven versehen.

Applications: Lettering for buildings, picture landscapes, advertising messages, selected colour design.

Für alle Verpressungen und Klebungen mit Holzwerkstoffen, Kunststoffen, Akkustikmaterial, Kunstleder, etc. Unzählige Gestaltungsmöglichkeiten mit der Vakuumpresse. Herstellung von neuen Formen und Gegenständen mit unterschiedlichsten Materialien.

Applications: carcasses, counters, whole laminated desks, covers, cladding, veneered profiles in cross and length direction, upholstery, coating with textiles.

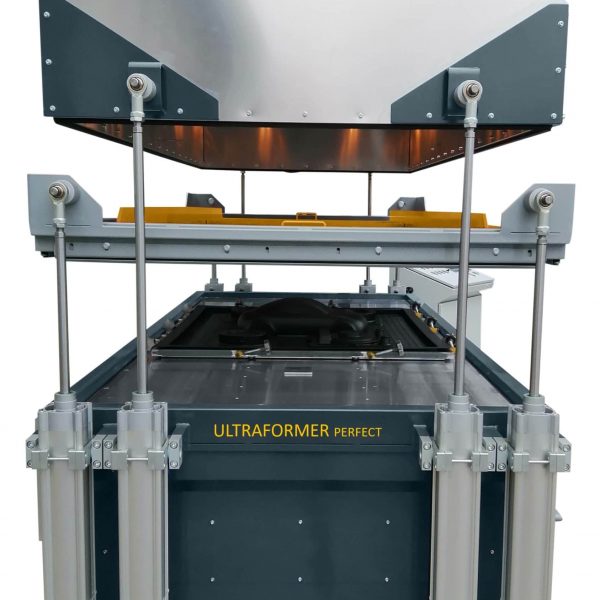

Thermoforming Press Ultraformer

The solution for all forming and pressing tasks!

Models and dimensions

3D-thermoforming - heating + forming - foil laminating – vacuum pressing - composites – sublimation

The full version with a perfect deep drawing kit for all tasks.

Utilises all features with intelligent processing programs.

vertical opening 650 mm

pressing surface L x B: 2880 x 1280 mm

overall dimensions L x B x H: 4000 x 2000 x 1800 mm

heating drawer, 230°C

heating surface L x B: 2600 × 1250 mm

vacuum pumps 80 m³/h, 100 m³/h, 140 m³/h

heating + forming - foil laminating – vacuum pressing - composites – sublimation

Combination of the heating drawer and the heating hood.

clamshell opening, work piece height approx. 500 mm

pressing surface L x B: 2880 x 1280 mm

overall dimensions L x B x H: 4000 x 2000 x 1800 mm

heating drawer, 230°C

heating surface L x B: 2600 x 1250 mm

vacuum pumps 40m³/h, 80m³/h, 100m³/h

foil laminating – vacuum pressing - composites – sublimation

For all foil laminating jobs, flat and tall parts - batch production or single parts.

*The thermoforming frame set saves foil and enables you to do professional 3D thermoforming!

clamshell opening, work piece height approx. 500 mm

pressing surface L x B: 2880 x 1280 mm

overall dimensions L x B x H: 4000 x 2000 x 1800 mm

vertical opening 650 mm

pressing surface L x B: 2880 x 1280 mm

overall dimensions L x B x H: 4000 x 2000 x 1800 mm

vacuum pumps 40m³/h, 80m³/h, 100m³/h, 140m³/h

Other dimensions and features on request..

ULTRAFORMER – the outstanding 3D thermoforming machine

- permanent hot air stream whilst forming (no “freezing” of the material)

- forming window of plastics can be precisely adjusted

- fast realisation of difficult shapes with the Thermoforming Press

- adjustable deep drawing frame saves materials

- cost-effective thermoforming with only 1 piece

- easy manipulation of the Thermoforming Press, also for extraordinary applications

An intensive training plus continuing support make the ULTRAFORMER a success story!

Ultraformer - The Multitasking Thermopress-Centre! Futureproof your business today!

Universalformers Eine Marke der Lechenauer GmbH www.lechenauer.at